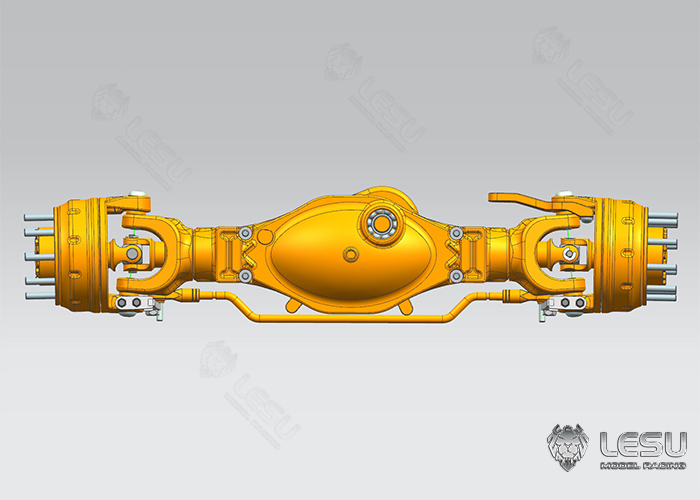

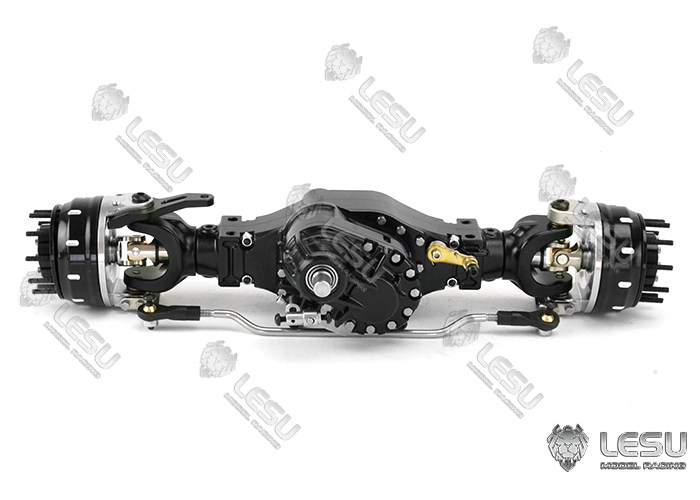

1/14 truck wheel reduction axle

Shell material: aluminum alloy, CNC precision machining.

Shell color: black

Surface treatment: oxidation treatment

Reduction ratio: 1:9.9

Suitable models: 1/14 Tamiya trucks and personal DIY modified vehicles

Install suspension: It is recommended to use X-8013-A suspension installation on the rear axle and rear middle axle. The front suspension uses X-8011.

Install wheel hubs: Install LESU flange hubs on the front axle and front through-axle.

When installing LESU rear axles and rear through-axles, only W-2048 can be installed on the rear hub.

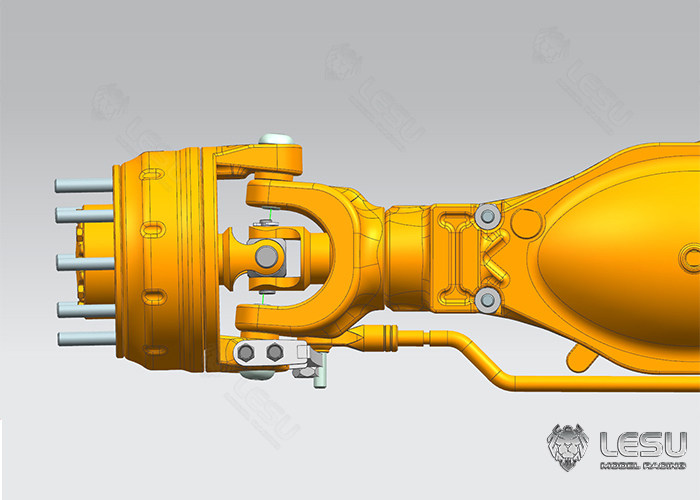

Highlight one, steering angle:

The steering transaxle has inclination angles, and these angles are not on the center line.

The saying in the professional field is: with front wheel camber, kingpin inclination and kingpin caster.

In other words, you can perform four-wheel alignment just like a real car! ! ! ! ! All positioning angles are opened,

allowing you to adjust them at will! This results in professional-grade performance, or ideal performance.

This product is protected by a patent

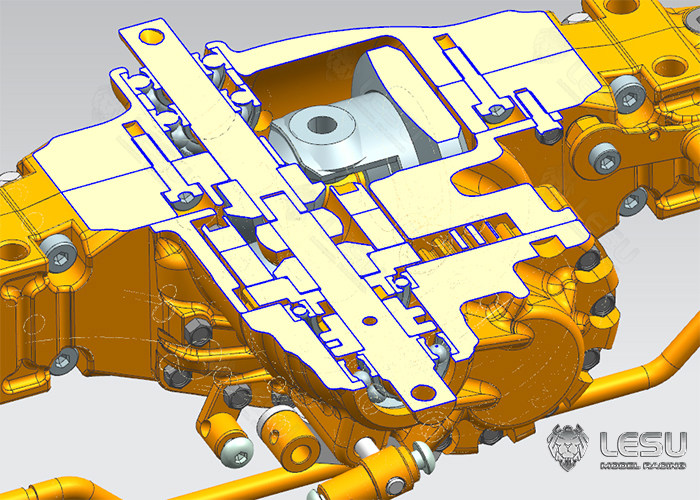

Highlight two:

The function of the model car's transaxle is to transfer the power generated by the engine or motor to the wheels after deceleration,

increase in torque, and reversal to drive the model car. When the model car is driven by multiple drive axles,

multiple sets of tires of the model car generate power. Therefore, when the car is turning or driving on a rough road,

the paths passed by each drive axle are inconsistent, which will result in no inter-axle differential.

There will be rotational speed interference between the drive axles, making the car unable to drive normally,

resulting in abnormal wear of the car's tires and easy damage to parts.

Therefore, adding an inter-axle differential between each drive axle can solve the problems

caused by the drive wheels when the car turns or drives on rough roads, making the movement of each axle wheel more reasonable.

advantage:

1. Strong controllability. The speed of each tire of the drive axle with inter-axle differential can be freely adjusted according to different situations.

Steering interference is avoided when turning. Therefore, the tires on each axle can perform pure rolling motion, so it is better than the axleless drive axle.

The car with the differential drive axle has better controllability and makes the car drive more rationally.

2. The space is compact. Integrating the inter-axle differential into the drive axle can reduce the number of

parts and save a separate transfer case, taking up less space in the model car.

Design concept restoration

On a real vehicle, the function of the axle drive device is to transmit the power generated by the engine or

motor to the axle, thereby driving the vehicle through the axle.

For some medium and large vehicles, the axle drive device will be used to drive two axles,

so that the wheels on the corresponding axles will generate power. When the vehicle turns or drives on a rough road,

the paths and distances traveled by each wheel are different, which will cause rotational speed interference between different axles,

making the vehicle unable to drive normally, and thus causing abnormal tire production. wear and tear.

When some wheels on the first axle or the second axle slip,

the inter-axle differential can be locked through the combination of the power input shaft and the driving gear.

When the inter-axle differential is in a locked state,

both output ends of the inter-axle differential rotate synchronously with the power input shaft and the first power output shaft.

At this time, the power input shaft directly passes through the driving gear and the driven gear.

The gear drives the second power output shaft to rotate, thereby ensuring that the first axle and the second axle obtain sufficient torque to enable the vehicle to travel normally.

When the vehicle is turning or driving on a rough road,

the inter-axle differential can be unlocked by separating the power input shaft from the driving gear.

When the inter-axle differential is in the unlocked state,

the torque of the power input shaft is divided into two parts through the two output ends of the inter-axle differential:

one part is transmitted to the first power output shaft, and the other part passes through the driving gear and the driven gear.

The gear is transmitted to the second power take-off shaft.

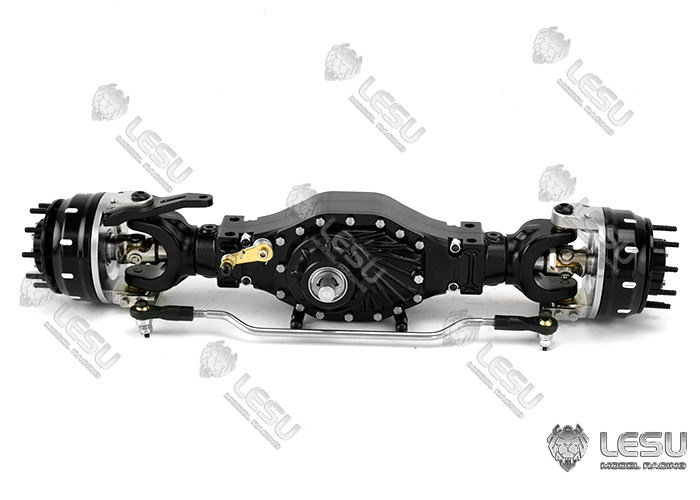

Actual photos: (blue and gray are the previous versions, now all are black versions)

Q-9030 wheel reduction front axle:

Q-9029 wheel side deceleration front through bridge:

Q-9028 wheel rim deceleration rear through bridge:

Q-9027 wheel side reduction rear axle:

Q-9032 inter-axle differential wheel side reduction front through-axle:

Q-9031 inter-axle differential wheel side reduction rear through-axle: